- HOME

- Deep Foundation

- Typical method

- By using Sanwa Doughnut Auger

By using Sanwa Doughnut Auger

DOUGHNUT AUGER Method

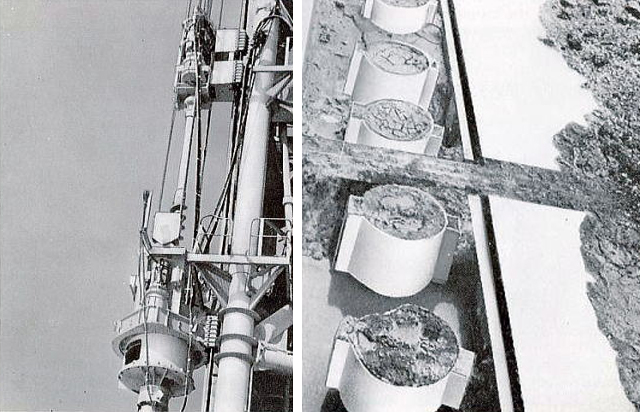

DOUGHNUT AUGER is very unique in the world due to its mechanism and applications. The principal mechanism of DOUGHNUT AUGER exists in the combination of Auger Flight which is rotated clockwise, and the steel tube which is rotated counter-clockwise. Steel tube can be smoothly driver or extracted, because the rotation of steel tube cuts circumferential friction while Auger Flight and Auger Head, which are inserted in the steel tube, bore at the same time. Accordingly, DOUGHNUT AUGER offers the following big advantages.

| High | The outside steel tube encloses Auger Flight and it keeps straight-ness of bored hole. |

|---|---|

| Accuracy | This advantage strongly appears in case of oblique and deep borings. |

| Protection of Bored Hole | In case of PIP and MIP methods by using conventional Earth Auger, bored hole can not be completely protected if underground pressurized water layer is encountered. On this occasion, DOUGHNUT AUGER is its solution due to the simultaneous driving of the steel tube which protects the bored hole completely. |

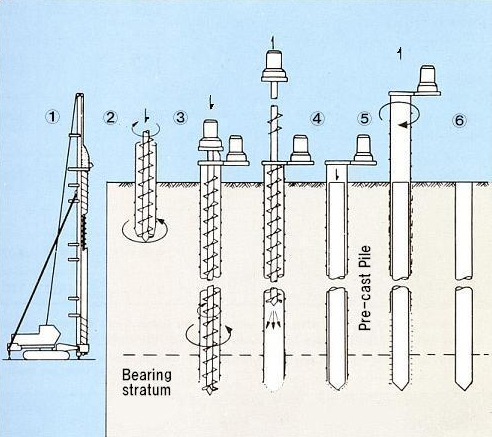

DOUGHNUT AUGER is classified SMD and SDA types

SMD Type

Single gear transmission rotates Auger Flight and steel tube, in reverse direction each other.

SDA Type

Double gear transmissions are equipped. One gear transmission rotates Auger Flight and the other one rotates steel tube. Each trans-mission is independently operated.

So, the rotation of Auger Flight and steel tube is freely changeable to forward and reverse directions and each transmission can be freely moved up and down along with the leads to obtain high degree of boring efficiency.

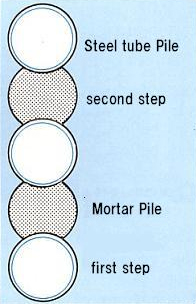

For Pre-Cast Concrete Pile

- 1Set up the equipment

- 2Augering : Inner Drive Unit-clockwise rotation (Auger Flight).

Outer Drive Unit counterclock wise rotation (Casing). - 3Reach the desired depth

- 4Stop the rotation : The Inner Drive Unit is extracted while grouting the Cement-Mortar.

- 5Insert the pile into the Casing.

- 6Outer Drive Unit is extracted while clockwise rotating so that the augered soil, which is placed around the pile on the ground, is replaced into the gap of pile and bored hole.

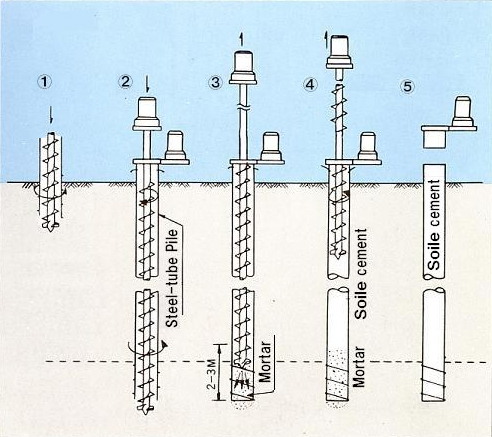

For Steel-Tube Pile

- 1Augering : Inner Drive Unit-clockwise rotation (Auger Flight).

Outer Drive Unit-counterclock wise rotation (Steel-tube pile). - 2Reach the desired depth

- 3Injecting mortar through the Auger Head while Inner Drive Unit is extracted by approx. 2 to 3m then insert the Auger Head again.

- 4The rotation of Inner Drive Unit is counterclockwise for replacing the Augered soil into the Steel-tube Pile.

- 5Outer Drive Unit is detached from steel-tube Pile.