- HOME

- Deep Foundation

- Typical method

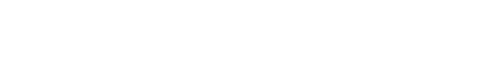

- For M.I.P method(Mixed in place pile)

For M.I.P method(Mixed in place pile)

MIP method is a sort of cast-in-place piling and it is to execute "Soil Pile" which is consolidated with in-place soil and cement slurry. MIP equipments are composed of Auger Drive Unit, Driving Hollow Shaft without helical blade, Mixing Heads equipped with Mixing Blades, and Cement Slurry Mixing & Pumping Plant. Driving Shaft is inserted into soil while it is rotated by Auger Drive Unit, and Mixing Heads forcible mixes in-place soil with cement slurry injected through the valves built in Mixing Head. Mixing Head is moved up and down so that cement slurry should be uniformly mixed with soil, and then Soil Pile is executed at site. MIP method is applicable for underground soil-retaining and watertight wall and low grade bearing pile.